When planning a construction or landscaping project that involves drainage, selecting the right culvert is a crucial decision. The choice of culvert can significantly impact the efficiency and longevity of your project. With various types of culverts available, it’s essential to understand the differences to make an informed decision. In this guide, we’ll walk you through the key considerations for choosing the right culvert for your specific needs.

Understanding Culvert Types

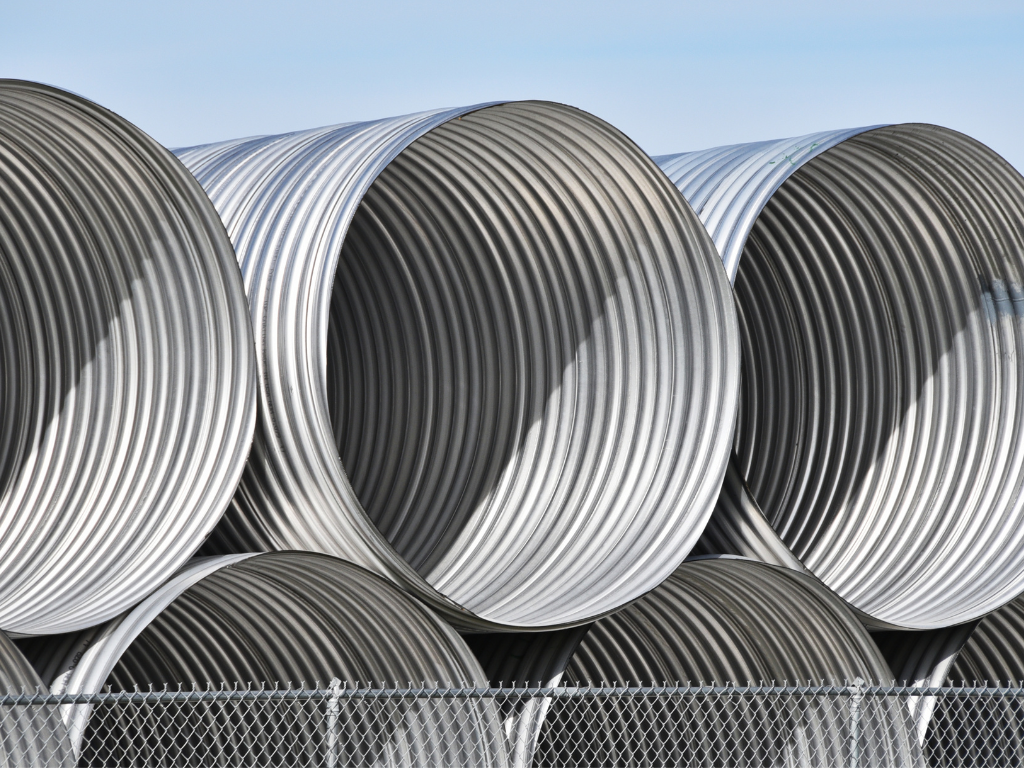

Galvanized Steel Culverts

Galvanized steel culverts are a popular choice for many projects due to their durability and cost-effectiveness. These culverts are coated with zinc, providing a layer of protection against rust and corrosion. They are ideal for drainage systems in rural areas, driveways, and access roads. Typically classified as a 50-year pipe, galvanized steel culverts offer a solid balance between cost and longevity.

Aluminized Steel Culverts

Aluminized steel culverts are a step up from galvanized options, offering enhanced corrosion resistance. These culverts are coated with an aluminum-silicon alloy, which provides better protection in environments with alkali soils, saltwater, or other erosive conditions. Classified as a 75-year pipe, aluminized steel is an excellent choice for projects where durability is paramount.

Polymer-Coated Culverts

For projects requiring the highest level of protection, polymer-coated culverts are the top choice. These culverts are coated with a heavy-gage polymer laminate, offering exceptional resistance to abrasion and corrosion. Classified as a 100-year pipe, polymer-coated culverts are ideal for long-term infrastructure projects, such as storm drains and sewer systems, where harsh environmental conditions are expected.

Reinforced Concrete Pipe (RCP)

Reinforced Concrete Pipe (RCP) is known for its strength and durability, making it suitable for high-load applications. RCP is often used in municipal projects, including storm sewers and culverts. It is available in various diameters, and when paired with Pre-Cast Concrete Safety End Treatments (SETS), it meets the requirements for most State Highway road entrances. RCP’s long lifespan and structural integrity make it a reliable choice for large-scale projects.

Factors to Consider When Choosing the Right Culvert

Environmental Conditions

The environmental conditions of your project site play a significant role in choosing the right culvert. For example, areas with high salt content or acidic soils may require aluminized or polymer-coated culverts to prevent corrosion.

Project Budget

While polymer-coated culverts offer the highest level of durability, they are also the most expensive option. Balancing the cost with the expected lifespan and performance of the culvert is crucial in making the right decision.

Load Requirements

Consider the load requirements of your project. If your culvert will be subject to heavy traffic, such as in roadways or commercial properties, reinforced concrete or polymer-coated steel culverts are better suited for the task.

Regulatory Compliance

Ensure that the culvert you choose meets any local or state regulations, especially for public infrastructure projects. For example, RCP with SETS is often required for State Highway entrances.

Conclusion

Choosing the right culvert for your project involves careful consideration of the environmental conditions, budget, load requirements, and regulatory standards. By understanding the strengths and limitations of each type of culvert, you can make an informed decision that ensures the success and longevity of your project. Whether you opt for galvanized steel, aluminized steel, polymer-coated, or reinforced concrete, selecting the right culvert is key to achieving optimal drainage and infrastructure performance.